April 16, 2015 – Z-AXIS, Inc. has added high-performance 3D printing to its electronics design and contract manufacturing facility near Rochester, NY. The company will use its new Airwolf AW3D HD2X printer to create prototype enclosures for electronic products that Z-AXIS designs and manufactures for its customers.

“3D printing of enclosure prototypes is a great extension of our existing printed circuit board prototyping capabilities,” said Michael Allen, president of Z-AXIS. “With this higher-end 3D printer, our engineers can design and produce a prototype enclosure in less than a day. It enhances our ability to deliver complete, elegant prototype assemblies at a reasonable cost.”

Z-AXIS’ customers include medical, commercial and industrial equipment manufacturers who often have unique constraints and cannot use standard enclosures for their printed circuit board assemblies. While custom enclosures from plastic or metal fabricators are economical in high volumes, the prototypes are expensive and take weeks to procure. Z-AXIS can now provide the prototypes faster and cheaper, and quickly turn around any needed changes after customer review and test.

In addition to customer prototypes, Z-AXIS will use its new 3D printer to create jigs and fixtures for its own manufacturing operations. For example, the company can print tube holders for the part feeders on its pick and place machines, using static dissipative material for ESD protection. This allows the manufacturing team to reduce the cost of accommodating a wide range of component tubes.

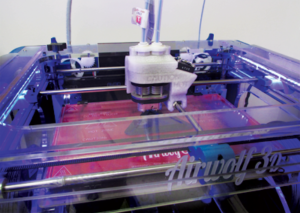

The Airwolf AW3D HD2X can print objects using two different materials at once, allowing Z-AXIS to create complex structures. It has an 11 x 8 x 12 inch capacity with 0.002 inch layer-to-layer resolution.